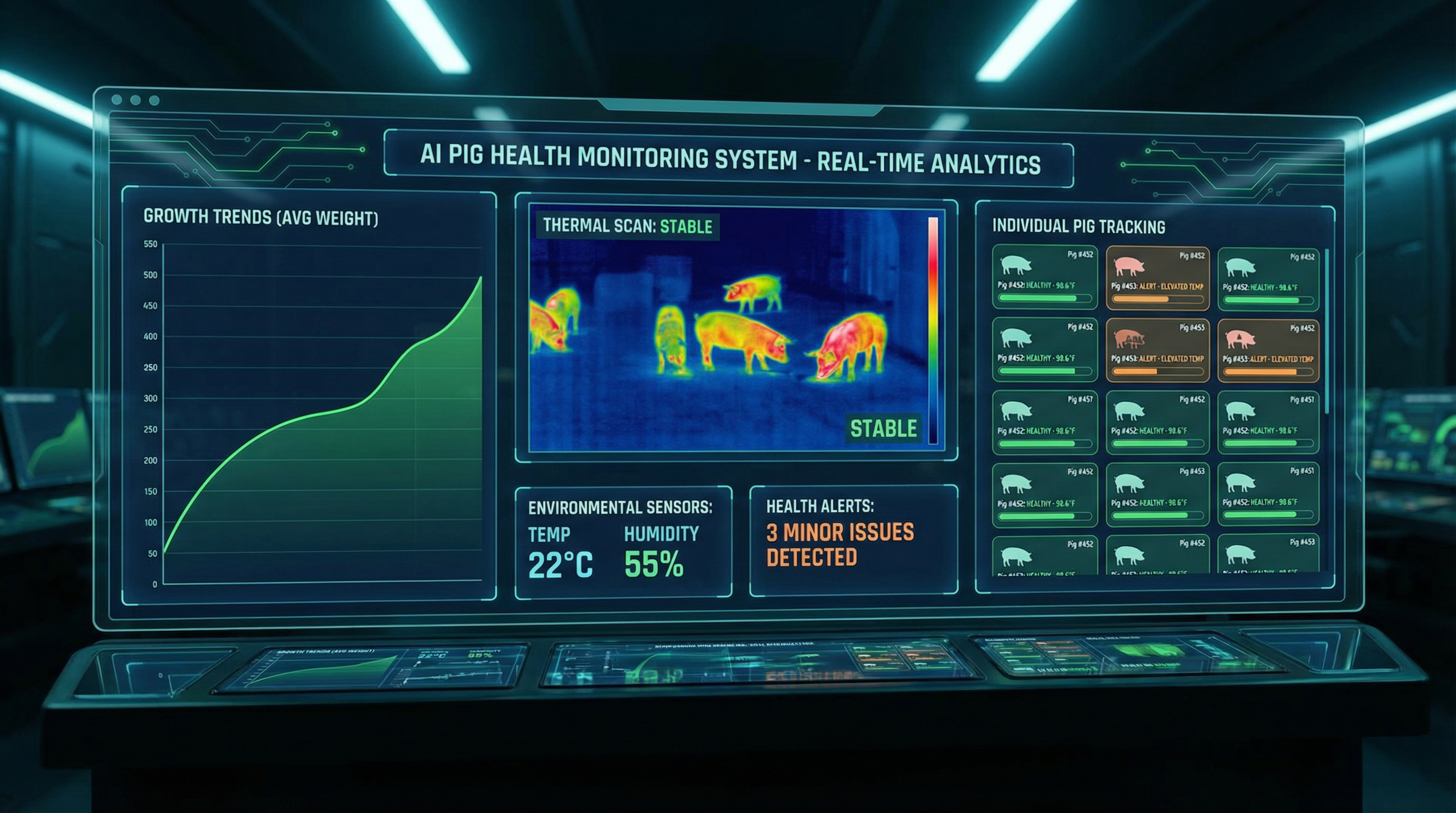

The global pork industry stands at a crossroads. Faced with persistent challenges such as labor shortages, the ever-present threat of disease outbreaks, and razor-thin profit margins, traditional pig farming methods are proving increasingly unsustainable. The demand for higher efficiency, improved animal welfare, and greater transparency has never been more urgent. In this landscape of challenge and opportunity, agricultural technology (AgTech) is emerging as a powerful force for change. One company at the forefront of this transformation is Trackfarm, a South Korean startup that is redefining the standards of pig farming with its comprehensive, AI-driven smart livestock solution.\n\nTrackfarm offers an integrated system that combines artificial intelligence, IoT hardware, and data analytics to create a fully optimized farming environment. This is not merely about automation; it is about creating an intelligent, responsive, and predictive ecosystem that empowers farmers to manage their operations with unprecedented precision and efficiency. By tackling the entire value chain, from individual animal monitoring to environmental control and data-driven decision-making, Trackfarm is building a new paradigm for the future of pork production.\n\n## The Core Technology: AI-Powered Monitoring\n\nThe centerpiece of Trackfarm’s solution is its sophisticated AI-powered monitoring system. Moving far beyond simple surveillance, the system utilizes a network of high-resolution and thermal imaging cameras to continuously observe the livestock. Using advanced computer vision algorithms, the software can identify and track each pig individually, creating a unique digital profile for every animal on the farm.\n\nThis individual-level monitoring is a game-changer. The AI analyzes behavioral patterns, such as feeding habits, water intake, activity levels, and even social interactions. By establishing a baseline for normal behavior, the system can instantly detect anomalies that may indicate illness, stress, or other health issues, often before they would be noticeable to the human eye. For instance, a pig that is suddenly lethargic or has reduced its feed intake can be flagged for immediate attention.\n\n \n\nThermal imaging adds another critical layer of data. By monitoring the body temperature of each pig, the system can detect fever, a primary indicator of infection. This early warning capability is crucial for preventing the spread of diseases like African Swine Fever (ASF), which can devastate entire farms. The combination of visual and thermal data provides a holistic health profile for each animal, enabling proactive and preventative care rather than reactive treatment.\n\n

\n\nThermal imaging adds another critical layer of data. By monitoring the body temperature of each pig, the system can detect fever, a primary indicator of infection. This early warning capability is crucial for preventing the spread of diseases like African Swine Fever (ASF), which can devastate entire farms. The combination of visual and thermal data provides a holistic health profile for each animal, enabling proactive and preventative care rather than reactive treatment.\n\n \n\n## Hardware Integration: The Smart IoT Ecosystem\n\nTrackfarm’s AI is not just a passive observer; it is the brain of a fully integrated smart farm. The software is connected to a suite of proprietary IoT hardware modules that actively manage the barn environment. These modules include sensors that constantly monitor critical environmental parameters such as temperature, humidity, ammonia levels, and carbon dioxide.\n\nWhen the system detects that conditions are deviating from the optimal range, it can automatically trigger adjustments. For example, if the temperature rises, the system can activate ventilation fans or misters. If ammonia levels climb, it can increase air circulation to ensure a healthy and comfortable environment for the pigs. This automated control eliminates guesswork and ensures that the animals are always in an environment optimized for their growth and well-being. This level of control has been shown to reduce the growth cycle by 2-3 weeks, a significant boost in productivity.\n\nThis automation dramatically reduces the labor required to manage a large-scale operation. A single farm manager can oversee a herd of over 3,000 pigs through a centralized platform, freeing up human resources to focus on higher-value tasks. The system effectively replaces up to 99% of the manual labor associated with individual pig management, addressing one of the most significant challenges in the industry.\n\n## Data as the New Feed: Analytics and Optimization\n\nAll the information collected by the cameras and sensors is streamed to a cloud-based platform for analysis. This is where Trackfarm transforms raw data into actionable intelligence. The platform uses data mining and machine learning algorithms to analyze trends, identify correlations, and generate predictive insights.\n\nFarmers can access a comprehensive dashboard that visualizes key performance indicators (KPIs) for their entire operation. This includes growth rate projections, feed conversion ratios, health metrics, and environmental data. The system doesn’t just present data; it provides clear, concise guidelines and alerts to help farmers make informed decisions.\n\n

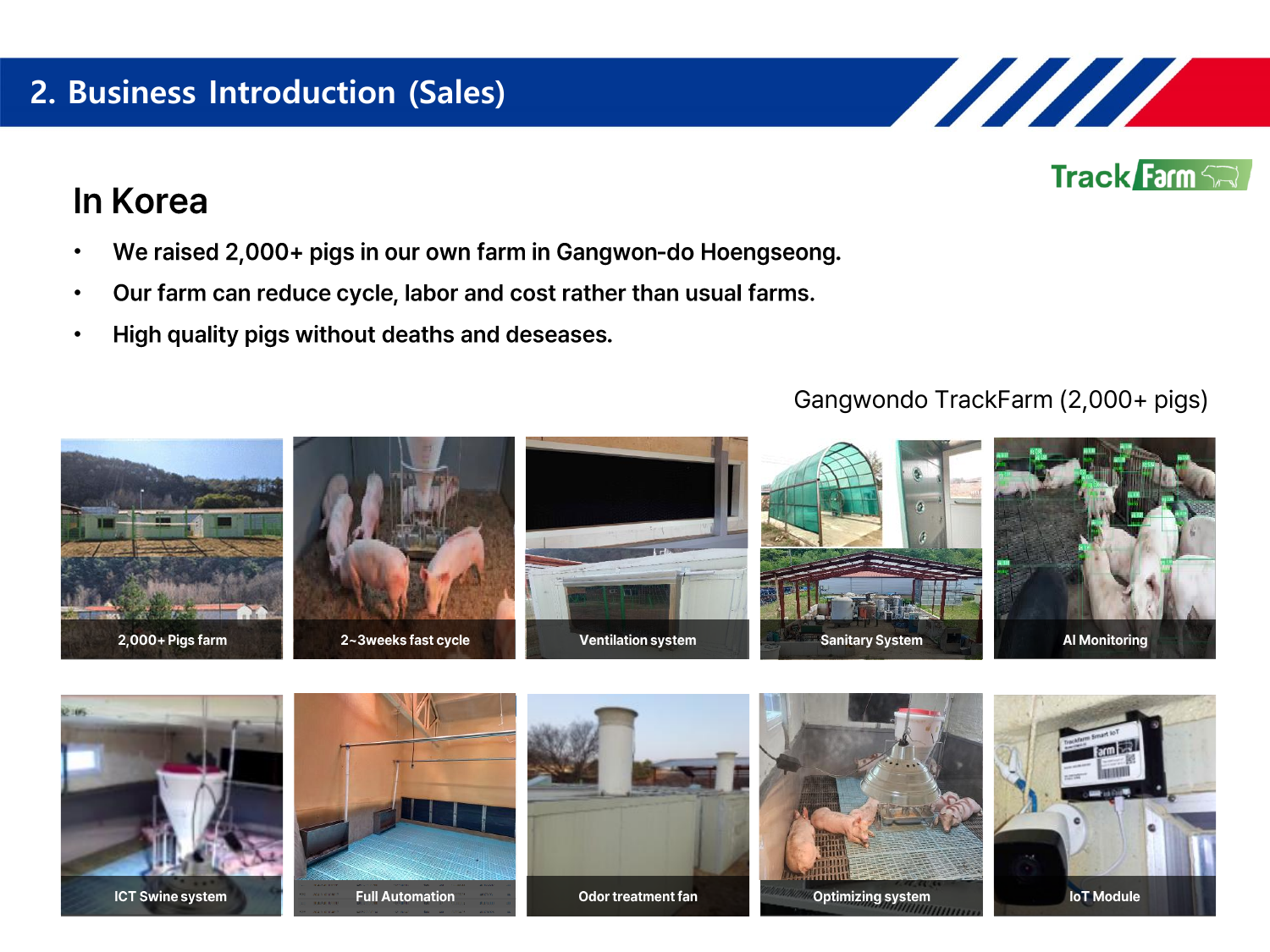

\n\n## Hardware Integration: The Smart IoT Ecosystem\n\nTrackfarm’s AI is not just a passive observer; it is the brain of a fully integrated smart farm. The software is connected to a suite of proprietary IoT hardware modules that actively manage the barn environment. These modules include sensors that constantly monitor critical environmental parameters such as temperature, humidity, ammonia levels, and carbon dioxide.\n\nWhen the system detects that conditions are deviating from the optimal range, it can automatically trigger adjustments. For example, if the temperature rises, the system can activate ventilation fans or misters. If ammonia levels climb, it can increase air circulation to ensure a healthy and comfortable environment for the pigs. This automated control eliminates guesswork and ensures that the animals are always in an environment optimized for their growth and well-being. This level of control has been shown to reduce the growth cycle by 2-3 weeks, a significant boost in productivity.\n\nThis automation dramatically reduces the labor required to manage a large-scale operation. A single farm manager can oversee a herd of over 3,000 pigs through a centralized platform, freeing up human resources to focus on higher-value tasks. The system effectively replaces up to 99% of the manual labor associated with individual pig management, addressing one of the most significant challenges in the industry.\n\n## Data as the New Feed: Analytics and Optimization\n\nAll the information collected by the cameras and sensors is streamed to a cloud-based platform for analysis. This is where Trackfarm transforms raw data into actionable intelligence. The platform uses data mining and machine learning algorithms to analyze trends, identify correlations, and generate predictive insights.\n\nFarmers can access a comprehensive dashboard that visualizes key performance indicators (KPIs) for their entire operation. This includes growth rate projections, feed conversion ratios, health metrics, and environmental data. The system doesn’t just present data; it provides clear, concise guidelines and alerts to help farmers make informed decisions.\n\n \n\nBelow is a table illustrating the relationship between the data collected and the optimizations enabled by the Trackfarm platform:\n\n| Data Point Collected | Analysis Performed | Resulting Optimization |\n| :— | :— | :— |\n| Individual Feed Intake | Feed Conversion Ratio (FCR) Analysis | Optimized feed formulation and allocation |\n| Body Temperature (Thermal) | Fever Detection & Trend Analysis | Early disease detection and quarantine protocols |\n| Activity & Behavior Patterns | Anomaly Detection | Proactive health interventions and stress reduction |\n| Ambient Temperature/Humidity | Environmental Fluctuation Analysis | Automated climate control for optimal growth |\n| Weight Estimation (Vision) | Growth Curve Prediction | Precise timing for market readiness and slaughter |\n| Air Quality (Ammonia, CO2) | Health Risk Assessment | Automated ventilation adjustments |\n\nThis data-driven approach allows for continuous improvement and optimization. The system learns over time, refining its algorithms and providing increasingly accurate predictions and recommendations. It transforms farming from a practice based on tradition and intuition into a science based on empirical evidence.\n\n## The Business Case: From Farm to Table\n\nTrackfarm’s vision extends beyond simply selling technology. The company operates a vertically integrated business model that proves the value of its own solution. Through its premium pork brand, DayFarm, Trackfarm manages its own R&D farms in Korea and is expanding its operations in Vietnam, one of the world’s largest pork markets.\n\nThis allows the company to not only generate revenue from pork production but also to continuously test, refine, and showcase its technology in a real-world environment. The business model encompasses:\n\n1. Farming HW/SW Solution Sales: Licensing the technology to other farms.\n2. Pig Farming: Producing high-quality pork under the DayFarm brand.\n3. Meat Processing & Cold-Chain: Expanding into downstream operations to ensure quality control from production to consumption.\n\n

\n\nBelow is a table illustrating the relationship between the data collected and the optimizations enabled by the Trackfarm platform:\n\n| Data Point Collected | Analysis Performed | Resulting Optimization |\n| :— | :— | :— |\n| Individual Feed Intake | Feed Conversion Ratio (FCR) Analysis | Optimized feed formulation and allocation |\n| Body Temperature (Thermal) | Fever Detection & Trend Analysis | Early disease detection and quarantine protocols |\n| Activity & Behavior Patterns | Anomaly Detection | Proactive health interventions and stress reduction |\n| Ambient Temperature/Humidity | Environmental Fluctuation Analysis | Automated climate control for optimal growth |\n| Weight Estimation (Vision) | Growth Curve Prediction | Precise timing for market readiness and slaughter |\n| Air Quality (Ammonia, CO2) | Health Risk Assessment | Automated ventilation adjustments |\n\nThis data-driven approach allows for continuous improvement and optimization. The system learns over time, refining its algorithms and providing increasingly accurate predictions and recommendations. It transforms farming from a practice based on tradition and intuition into a science based on empirical evidence.\n\n## The Business Case: From Farm to Table\n\nTrackfarm’s vision extends beyond simply selling technology. The company operates a vertically integrated business model that proves the value of its own solution. Through its premium pork brand, DayFarm, Trackfarm manages its own R&D farms in Korea and is expanding its operations in Vietnam, one of the world’s largest pork markets.\n\nThis allows the company to not only generate revenue from pork production but also to continuously test, refine, and showcase its technology in a real-world environment. The business model encompasses:\n\n1. Farming HW/SW Solution Sales: Licensing the technology to other farms.\n2. Pig Farming: Producing high-quality pork under the DayFarm brand.\n3. Meat Processing & Cold-Chain: Expanding into downstream operations to ensure quality control from production to consumption.\n\n \n\nBy controlling the entire process, Trackfarm can guarantee the quality, safety, and traceability of its products, creating a premium brand that consumers can trust. This integrated strategy provides a powerful validation of their technology and a scalable model for future growth, with ambitious plans to expand throughout Southeast Asia and globally.\n\nIn conclusion, Trackfarm is not just another AgTech company. It is an architect of the future of livestock farming. By seamlessly integrating AI, IoT, and data analytics, it has created a solution that addresses the industry’s most pressing challenges. The result is a system that is more efficient, more sustainable, and more humane, paving the way for a new generation of smart agriculture that will feed the world of tomorrow.

\n\nBy controlling the entire process, Trackfarm can guarantee the quality, safety, and traceability of its products, creating a premium brand that consumers can trust. This integrated strategy provides a powerful validation of their technology and a scalable model for future growth, with ambitious plans to expand throughout Southeast Asia and globally.\n\nIn conclusion, Trackfarm is not just another AgTech company. It is an architect of the future of livestock farming. By seamlessly integrating AI, IoT, and data analytics, it has created a solution that addresses the industry’s most pressing challenges. The result is a system that is more efficient, more sustainable, and more humane, paving the way for a new generation of smart agriculture that will feed the world of tomorrow.